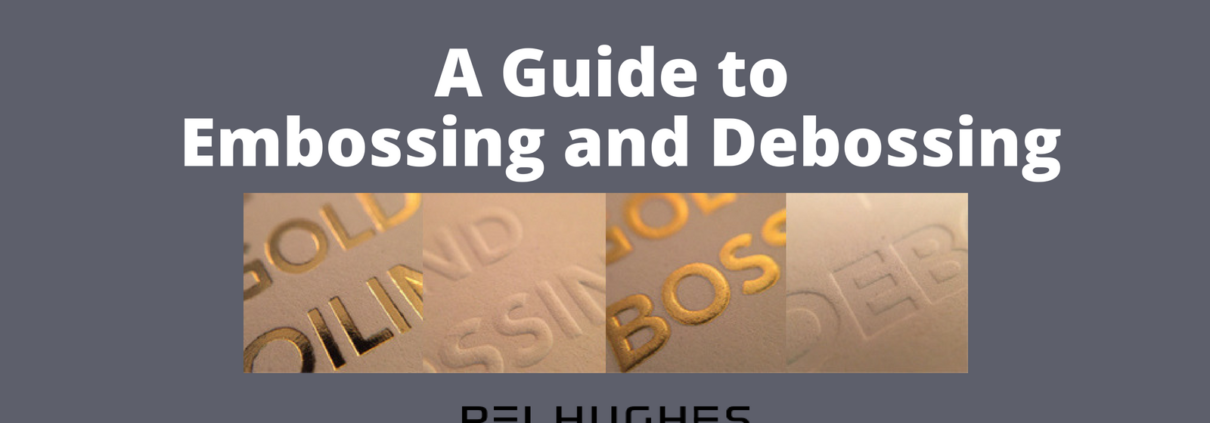

A guide to embossing and debossing

Embossing and debossing are both great ways to enhance your prints and bring attention to specific elements of your design. These processes add texture to business cards, post cards, brochures and more, by creating raised or depressed areas on the paper. Highlight important details, such as logo, graphic, or names! Adding a tactile dimension to your print is a memorable way to impress your customers and communicates premium quality.

What is Embossing?

Embossing uses a die (personalized metal plate) to slightly raise images off the paper of your print piece. It creates a 3D effect that brings emphasis to whatever area you’re having embossed.

Embossing is made using two dies, a “front” and a “back” that sandwich the paper and create the 3D effect. The most effective embossed pieces use a detailed die and heavier paper stock to highlight the depth and detail of the embossed graphics or images.

What is debossing?

You can think of debossing as the opposite of embossing. Debossing is when an image (logo, text, etc.) is imprinted into your print piece, creating a depressed effect. Just like embossing, you can choose to leave the debossed area untouched or fill it in with ink or foil stamping.

Unlike embossing, debossing doesn’t interfere with the back of your print piece, giving you both sides to work with. It can be used on its own, or in conjunction with embossing.

Things to know about embossing & debossing

- Rule thickness. Fine lines and text appear thinner when embossed versus being printed offset. Request a rule reference sheet to properly specify your rule widths before manufacturing.

- Small text. Text naturally loses character density when embossed, which can be compensated for in the design or prepress stages. Discuss your design goals with your consultant to ensure the end result is one you anticipate.

- Because of the pressure, the bruise that is created on back of sheet may interfere with information on other side.

- Single-level embossing refers to a die that is etched to one depth. Multi-level or sculptured embossing dies have multiple levels of depth etched in the die creating a sculptured look.

- Add time to your schedule. Multi-level Embossing dies are often handcrafted, which adds 3 to 7 days to a production schedule, notwithstanding other scheduling and manufacturing considerations.

Talk to a Pel Hughes printing professional today about using embossing or debossing for your next project.